|

| Figure 1: Teledyne LeCroy's HDO8108A sports a very low noise floor of about 145 μV |

But before we get into the issue itself, let's take a step back for a moment. It's always important to understand the capabilities (and limitations) of your oscilloscope, because armed with that knowledge, you can better anticipate what your measurements will yield.

|

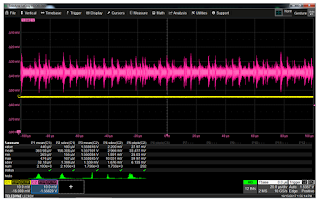

| Figure 2: This screen capture shows an acquisition of the inherent amplifier noise of the HDO8108A |

Consider the example of Teledyne LeCroy's HDO8108A oscilloscope (Figure 1), which offers a bandwidth of 1 GHz, eight analog input channels, and 12-bit vertical resolution. It also happens to be the instrument we'll use for the measurement examples to follow. We can observe the instrument's internal amplifier noise by simply grounding an input channel, and the result appears in Figure 2. Thanks to the HDO's vertical resolution, we can get a pretty accurate measurement.

|

| Figure 3: Noise measurements can be thought of in terms of RMS value or standard deviation |

From Figure 3, we can see that the standard deviation of the noise-floor trace of Figure 2 is about 145 μV. So now we have an idea of what the HDO8108A is capable of in terms of noise measurements.

|

| Figure 4: Initial measurement results from a 1.5-V battery |

At the top in Figure 4 is our battery (in magenta, Ch2); below that is our noise-floor measurement for reference (in yellow, Ch1), with both on the same vertical scale. We see noise on our battery's voltage, lots of it, and way more than we expected. We're measuring a mean voltage of 1.56 V, 3 V RMS, and a noise level of 33 mV peak to peak.

|

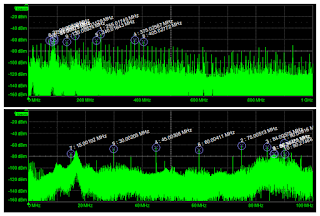

| Figure 5: A spectrum analysis view of the battery's voltage measurement |

One consistency check we can do, thanks to the HDO8108A's fast-Fourier analysis capabilities, is to look at this signal in the frequency domain (Figure 5). From the full-spectrum frequency plot at top, we see that the noise is indeed very wide-band in nature, reaching to the oscilloscope's full bandwidth of 1 GHz with no sign of petering out.

At the bottom of Figure 5 is a zoomed view of the first 100 MHz of the spectrum, and there are clear peaks in the noise, which, curiously, begin at almost exactly 15 MHz, followed by 30 MHz, 45 MHz, and so on. This is undoubtedly man-made RF noise on our battery signal.

|

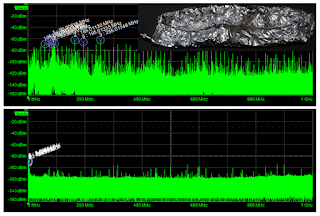

| Figure 6: Another spectrum analysis view of the battery voltage (with battery now properly shielded) |

The obvious remedy, then, is to provide some shielding for our 1.5-V battery. After carefully wrapping it in aluminum foil, we repeat the measurement, only to find that the noise spectrum is virtually identical to that of the first measurement. Huh?

Then we take a close, careful look at our shielded battery and case, and notice something: only the center conductor of the coax is making contact with the foil. The coax's shield is not; it's floating. And, of course, shielding is only really effective if it is connected to the return path to the instrument's chassis. With that coax shield disconnected from our foil around the battery, RF pickup will be unmitigated and will be transmitted to the signal line almost as it had with no foil at all.

|

| Figure 7: The oscilloscope's noise-floor measurement (yellow) and the shielded battery measurement (magenta) are virtually identical |

As a final sanity check, let's compare our battery noise with proper shielding to our oscilloscope's noise-floor measurement (Figure 7). That's the oscilloscope on Ch1 (yellow trace) and the battery on Ch2 (magenta trace), and they are virtually identical. In fact, the battery's noise is below the oscilloscope's noise floor.

What, then, have we discovered about how to reduce RF pickup in power-rail measurements?

- Whenever we probe low-level signals with anything other than a well-shielded coax connection, we will be encountering RF interference. Any exposed conductors that are separated from the DUT's shielding are going to act like antennas.

- Moreover, that RF pickup will typically be of a broadband nature. To minimize this aspect, we want our probe's tip to be designed as much like coax as possible. Any inductance in that tip will degrade your measurement bandwidth and probably cause some ringing in your measurements. But what's worse is you will get that "antenna effect" and the probe will be prone to RF pickup. So you want a connection between the oscilloscope and the DUT that looks as much like a coaxial connection as possible.

- In terms of design for test, if you can add test points to your board in the form of micro-coax connectors and then connect your coax cable to those points, you will have gone a long way toward killing any potential for RF interference in your measurements.

Stay tuned for more posts on power-rail measurements and how to make them count.

No comments:

Post a Comment