Preliminary drafts of the USB4 Compliance Test Specifications (CTS) were released to USB-IF work group members in early 2020 covering the electrical through protocol layer testing of USB4 router assemblies captive cable devices. These CTS documents define the required testing for USB4 hosts, hubs, and peripherals that make up the USB4 ecosystem. Thunderbolt 3 (TBT3) is also supported in USB4 end products and is tested using the existing TBT3 Host/Device CTS.

While the electrical test methodologies are similar to previous USB 3.2 compliance tests, USB4 is largely based off the TBT3 physical layer, and these test methods have been adopted. Here, we summarize the USB4/TBT3 test approach called out in the aforementioned documents.

USB4 Transmitter Testing

|

Figure 1. Test points TP2 and TP3 for USB4

Electrical Compliance Testing (Source: USB-IF) |

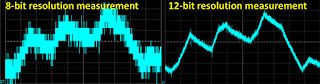

Presently, there is no SIG-TEST software for performing transmitter (Tx) testing, although it is anticipated that one will be released by the USB-IF in the future. All Tx tests performed by QPHY-USB4-TX-RX utilize Teledyne LeCroy methods, with measurements made directly by the oscilloscope.

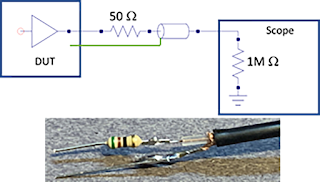

Figure 1 shows the Test points defined in the CTS for physical layer testing. Testing of the Tx-side is similar to those performed for USB 3.2 in that the signal is captured at the connector (TP2), where many measurements are defined. Then, a passive cable model is embedded and equalization is applied to result in TP3 measurements.